Tel: 400 6622 333

Detailed content

Operation Scope

Fit for recycling and dry stacking of dewatered fine-grained pulp materials

The first step of the process is to concentrate the fine-grained ore pulp with the concentration of 5-30% and 60% of-400 mesh fines by an high efficient thickener, producing pulp materials with high concentrations at 40-65%. The spilled clear water can be reused for production or be discharged if it meets the standards of water emission. The pulp with high concentrations entering the linear motion dewatering screen will be dehydrated for solid-liquid division. And the water ratio of the dry materials on the screens following successive processing will amount to 10-15%. Such materials also meet the requirements for dry stacking or transportation and can be dry stacked, reused, stored somewhere or landfilled according to different purposes. The screened materials will return to the thickener or thickening tank forming a closed cycle while the spilled clear water can be recycled or emitted.

Features

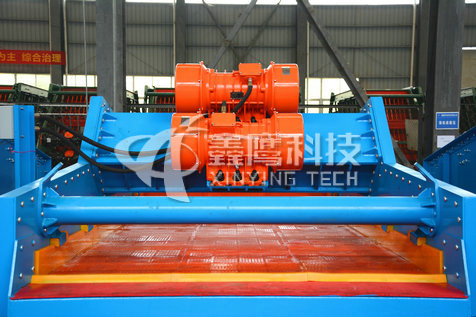

1.The linear motion dewatering screen is ideal for recovering and dehydrating solid materials from the pulp with low concentrations. With the screens pitching uphill 5° a feeding slurry pool naturally takes shape, whose static pressure can increase the amount of liquid crossing through the fine screens. Therefore, products on the screens will be continuously discharged from the screens.

2. The double vibrators installed rotating in opposite directions form a linear vibration mode on the entire screens, ensuring the forward transfer of solid materials on the screens.

3. The use of rubber springs will help diminish over 90% effects of vibration and less impact on the base. Such feature makes rubber springs more suitable for humid working conditions.

4. The anti-corrosion and moisture-proof design coupled with polyester glue coating on the screen surface and polyurethane screens makes sure the equipment can work normally despite operating in a wet and corrosive environment, thus prolonging the equipment’s service life.

5. There are no edges or cracks below the screen panel, which makes it impossible to retain wet materials. In such way, corrosion on the structure from wet materials can be reduced in maximum, preventing the occurrence of any cracks or ruptures.

6. The connection between structures adopts a “wet sealing” technology. Each surface at the joints will be meticulously grinded and then coated with two-layer epoxy primer, securing no corrosion on the surface.

7. The employment of high strength fitting bolt sets in its connection leaves no weld on the side plates, avoiding cases of stress concentration, deformation and cracking on the side plates because of heating.

8. The anti-flexural and -torsional features and higher strength and stiffness of the seamless steel tube serves as the beam with stress relief annealing after welding. Apart from the normal overload, the beam design also fully factors in its safety in order to adapt to the unpredictable environment and working conditions.

9. It is equipped with a high quality, high reliability and directional exciting force exciter that is eccentric block and grease lubricated. The vibrating force is adjustable with high efficiency and low maintenance costs. Moreover, the self-synchronization technology requires no forced connection between the two drive shafts, and the motor not to vibrate. The vibrator only produces low noise, usually at 76~78dB

10. The screen surface is a polyurethane slit panel . The slit joint is perpendicular to the direction of the material movement. And the opening is in general 0.1~0.2mm, It can be adjusted according to specific purposes. The end is equipped with an overflow weir plate whose height can be adjusted according to different requirements.

11. The pitching angle of the screen platform can be adjusted rapidly in order to accurately adjust the production process and realize the maximization of output and efficiency.

12. The height of the drain can be easily adjusted so as to better control the discharge of water.

13. The machine’s amplitude can be adjusted at any time to optimize its performance

14. Compared with the traditional dehydration screening equipment, It has higher production efficiency, lower total moisture content, and more convenient to transport dehydrated materials.

Technical Parameters

|

Model

|

Vibration Frequency (RPM)

|

Screening Area ( m2)

|

Handling Capacity (tons/h)

|

Motor Power (kw)

|

External Dimension L×W×H

|

|

ZZT-1536

|

1400

|

5.4

|

20-80

|

2×3

|

3840×2177×2630

|

|

ZZT-1836

|

9.5

|

30-100

|

2×5

|

3840×2477×2630

|

|

|

ZZT-2145

|

9.45

|

55-155

|

2×6.3

|

4740×2777×2630

|

|

|

ZZT-2160

|

12.6

|

90-210

|

2×8.4

|

6240×2777×2630

|

Package product

Related Projects

Order

Contact us

Add: Non-ferrous Industry Zone, Huangjin shan Economy Development District, Huangshi City, Hubei Province, China

Tel: 0086-714-3268866

Fax: 0086-714-3268800

Http://www.xinyingtec.com

www.xinyingkeji.com

E-mail: xinyintec@163.com

907916039@qq.com

Linear Motion Dewatering Screens

Linear Motion Dewatering Screens